|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

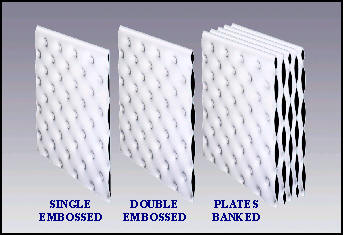

LASER WELDING VS. RESISTANCE WELDING The Power of Light Laser welding has proven to be the most efficient and cost-effective solution to conventionally-welded heat transfer surfaces with millions of square feet in operation today. We at Brune Engineered Products pride ourselves on our ability to produce high quality products while saving our customers time and money. Our CNC operated laser welding machines achieve optimal accuracy that allow flexibility that is unmatched by any other heat transfer welding process. Imagine a heating or cooling surface that is specifically designed for your application, with calculated process considerations that have been ignored or uncontrolled by conventional welding operations in the past. Now, imagine that this quality and assurance could be yours at no additional cost. This is the foundation of how Brune Engineered Products laser-welded surface has excelled in the heat transfer industry. We offer all our customers the convenience of on staff engineers to assist with any process questions or concerns that may arise. Heat Transfer Surfaces  Single-embossed panels are ideal for any application where a flat sanitary surface is required. Single embossed panels are utilized heavily for the process tank and cooling table/conveyor industries. Single-embossed panels are ideal for any application where a flat sanitary surface is required. Single embossed panels are utilized heavily for the process tank and cooling table/conveyor industries.Double-embossed plates are ideal for any process cooling or heating applications where sanitary surfaces are not required. Plate bank assemblies consist of double-embossed plates that have been assembled into banks to increase heat transfer surface density. All laser welded assemblies offer an option of a partial or full ASME "U" stamp.

|